News

Sonnenstromfabrik receives the "Top Brand PV© 2024" award

Sonnenstromfabrik, a leading German manufacturer of photovoltaic modules based in Wismar, has been honoured with the prestigious "Top Brand PV© 2024" award.

Read more … Sonnenstromfabrik receives the "Top Brand PV© 2024" award

Growing Interest in European Modules Confirms Sonnenstromfabrik's Strategy

Sonnenstromfabrik (CS Wismar GmbH), one of Europe's most modern manufacturers of high-quality photovoltaic modules, is drawing a positive conclusion from this year's Intersolar trade fair in Munich.

Read more … Growing Interest in European Modules Confirms Sonnenstromfabrik's Strategy

SONNENSTROMFABRIK CEO Dr. Bernhard Weilharter leaves the company

After eight years at the helm of the SONNENSTROMFABRIK / CS Wismar GmbH (SONNENSTROMFABRIK), Dr. Bernhard Weilharter will leave the company on June 30, 2023, to take on a new challenge outside the CENTROTEC Group.

Read more … SONNENSTROMFABRIK CEO Dr. Bernhard Weilharter leaves the company

"EXCELLENT" PV modules from Sonnenstromfabrik achieve the highest fire protection values in accordance with UNI 9177

SONNENSTROMFABRIK (CS Wismar GmbH), one of Europe's most leading and modern manufacturers of high-quality photovoltaic modules, successfully received the fire protection certificate in accordance with the UNI 9177 standard for its Glass/Glass and Glass/Foil Photovoltaic modules of the "EXCELLENT" series at the beginning of the year.

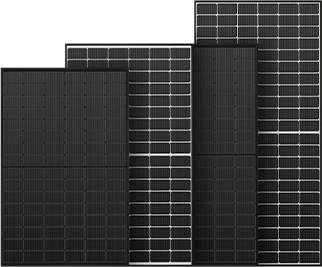

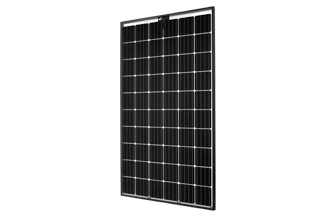

Product innovations: Sonnenstromfabrik introduces powerful module sizes with larger wafers and higher performance value-up to 490 Wp.

SONNENSTROMFABRIK (CS Wismar GmbH), one of Europe’s cutting-edge leaders in manufacturing high-quality photovoltaic modules, offers three new sizes for both glass/glass and glass/foil PV-panels from late autumn. Using a modern half-cut cell technology and a wafer size of 182mm² SONNENSTROMFABRIK’s PV-modules will achieve high performance values up to 490Wp.

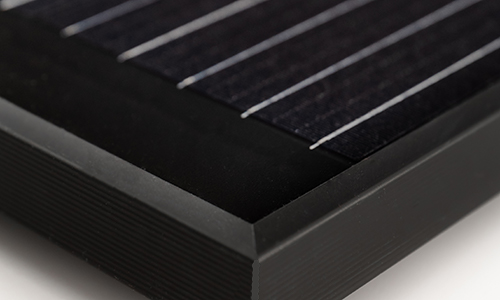

Design upgrade makes Sonnenstromfabrik’s black and full black glass/glass module even more durable

SONNENSTROMFABRIK (CS Wismar GmbH), one of Europe’s cutting-edge leaders in manufacturing high-quality photovoltaic modules, has advanced the design of its high-grade black and full black glass/glass modules. The integration of a black monolayer within the double-glass laminate makes the design even more stylish. The new design by SONNENSTROMFABRIK doesn’t just look good, it also makes the elegant PV modules even more durable.

Sonnenstromfabrik installs machinery for new generation of PV modules

SONNENSTROMFABRIK (CS Wismar GmbH), one of Europe’s cutting-edge leaders in manufacturing high-quality photovoltaic modules, has invested in new, state-of-the art machinery for the manufacture of solar cells up to 220 mm in size with half-cut and tri-cut cell technology. This prepares the company for the trend toward even larger wafer sizes, which will become the new global standard in the next few years.

Read more … Sonnenstromfabrik installs machinery for new generation of PV modules

Sonnenstromfabrik invests in fully automated final assembly facility for PV modules

SONNENSTROMFABRIK (CS Wismar GmbH), one of Europe’s cutting-edge leaders in manufacturing high-quality photovoltaic modules, has successfully made the final assembly stage of its high-quality PV modules fully automated and strengthened its quality assurance and quality control at the same time. The fully automated production line is equipped to manufacture PV modules with a total annual capacity of up to 200 MWp. SONNENSTROMFABRIK’s existing, partially automated, final assembly facility will remain in operation to ensure sufficient flexibility in manufacturing OEM products and special modules.

Read more … Sonnenstromfabrik invests in fully automated final assembly facility for PV modules

Sonnenstromfabrik increases sales by 30 percent in 2020

SONNENSTROMFABRIK (CS Wismar GmbH), one of Europe’s cutting-edge leaders in manufacturing high-quality photovoltaic modules, celebrated continued sustainable and profitable growth last year despite the negative economic impact of the Covid-19 pandemic. The company managed to increase the sales of its high-quality PV modules by 30 percent. As in previous years, the company closed out the 2020 financial year with a positive financial result, setting it apart from many of its competitors.

Read more … Sonnenstromfabrik increases sales by 30 percent in 2020

Housing development Houthaven Pier 2 is almost energy neutral thanks to a highly aesthetic, full-surface PV solution

SONNENSTROMFABRIK (CS Wismar GmbH), one of Europe’s cutting-edge leaders in manufacturing high-quality photovoltaic modules, has developed a full-surface photovoltaic installation for the hip roof covering 58 dwellings in Amsterdam’s new Houthaven quarter. Its innovative combination of a roof-mounted structure with aesthetic roof-integrated optics was designed and constructed by the technical engineering team at SONNENSTROMFABRIK in close collaboration with the client Oranjedak – a major player in the Dutch roofing industry.

SONNENSTROMFABRIK’s growth boosted by global group

SONNENSTROMFABRIK (CS Wismar GmbH), Europe’s cutting-edge leader in manufacturing high-quality photovoltaic modules, is becoming part of the group CENTROTEC Sustainable SE, based in Brilon, Germany.

Read more … SONNENSTROMFABRIK’s growth boosted by global group

Sonnenstromfabrik supplies transparent PV roof-integrated modules for “De Hollandsche Manege” in Amsterdam

Located at the heart of Amsterdam, the oldest horse-riding school in the Netherlands will be covered by transparent PV modules from Sonnenstromfabrik’s Brilliant module series.

Sonnenstromfabrik reports positive figures for 3rd quarter 2019

Sales increased by 50 percent compared to the same period of previous year. Business in Germany, the Netherlands, France and Switzerland is growing particularly positively.

Read more … Sonnenstromfabrik reports positive figures for 3rd quarter 2019

Sonnenstromfabrik supplies photovoltaic modules for sophisti-cated sun protection structures

Sonnenstromfabrik and Provence Eco Energie installed a high-transparent photovoltaic sun protection structure for the Collège de la Nativité in Aix-en-Provence.

Sonnenstromfabrik shows next step towards improving CO2 balance in energy mix

At the Svenska Solelmässan 2019 Dr. Bernhard Weilharter, Managing Director of Sonnenstromfabrik, pleaded at the end of October in Uppsala in front of an international trade audience for the reduction of CO2 emissions in the energy mix.

Read more … Sonnenstromfabrik shows next step towards improving CO2 balance in energy mix

Deliveries of new high-power PV modules has started

Our new high-power PV modules offer a good five percent better yield. The power output offered by the 60-cell PV modules has risen from 305 Wp to 320 Wp, or in some cases from 310 Wp to 325 Wp, thanks to a new design in combination with the familiar format.

Read more … Deliveries of new high-power PV modules has started

Boost in efficiency in photovoltaic systems through module innovation of the Sonnenstromfabrik

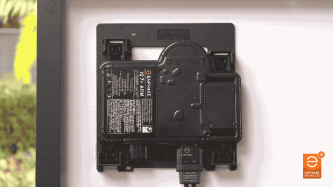

In May, Sonnenstromfabrik presented its newly developed AC modules at Intersolar in Munich. The core of the AC module technology is an integrated micro inverter from Enphase.

Sonnenstromfabrik expands in-roof module portfolio with three new Solrif glas foil modules

We have extended our glass/glass in-roof module series by glass/foil modules with 60, 54 and 48 cells. With the three new PV module formats in glass/foil design, lower-priced photovoltaic modules are now available as entry-level models for integrated solar roof concepts.

Sonnenstromfabrik is "Preferred Supplier" for Photovoltaic Modules for Dutch HEO system

Sonnenstromfabrik is a preferred supplier of the Dutch House Energy Optimum (HEO) system. HEO (www.bouwheo.nl) is a strategic alliance of A-brand suppliers of high-quality products and systems for insulation, shading, ventilation, heating, cooling and solar energy.

Read more … Sonnenstromfabrik is "Preferred Supplier" for Photovoltaic Modules for Dutch HEO system

April 2021

Sonnenstromfabrik kijkt terug op een succesvol zakelijk jaar 2020

Sonnenstromfabrik – onderdeel van CS Wismar GmbH – kijkt terug op een succesvol zakelijk jaar 2020. Door de coronapandemie fluctueerde de wereldwijde solar-markt continu. Sonnenstromfabrik profiteerde van deze instabiliteit: investeerders en projectleiders van solar-projecten kochten pv-modules lokaal in. Sonnenstromfabrik is gevestigd in Duitsland en maakt gebruikt van een toeleveringsnetwerk waardoor de planningszekerheid is gegarandeerd.

Read more … Sonnenstromfabrik kijkt terug op een succesvol zakelijk jaar 2020

Sonnenstromfabrik baut Maschinenpark für neue PV-Modul-Generation auf

Die SONNENSTROMFABRIK (CS Wismar GmbH), einer der modernsten und qualitativ führenden Hersteller von Photovoltaik-Modulen in Europa, investiert in einen neuen zukunftsweisenden Maschinenpark für die Produktion von PV-Modulen in Halb- und Drittelzell-Technologie für Zellen mit bis zu 220 mm Größe.

Read more … Sonnenstromfabrik baut Maschinenpark für neue PV-Modul-Generation auf

Sonnenstromfabrik développe son parc de machines pour la nouvelle génération de modules photovoltaïques

Sonnenstromfabrik (CS Wismar GmbH), l’un des fabricants leaders en Europe à pro-poser des modules solaires de haute qualité à la pointe de la technologie, investit dans un nouveau parc de machines d’avenir pour la production de modules photo-voltaïques avec des demi ou tiers-cellules mesurant jusqu’à 220 mm. L’entreprise an-ticipe ainsi l’évolution vers de plus grands formats de wafers qui deviendront la nou-velle norme internationale dans les prochaines années.

Sonnenstromfabrik installs machinery for new generation of PV modules

SONNENSTROMFABRIK (CS Wismar GmbH), one of Europe’s cutting-edge leaders in manufacturing high-quality photovoltaic modules, has invested in new, state-of-the art machinery for the manufacture of solar cells up to 220 mm in size with half-cut and tri-cut cell technology. This prepares the company for the trend toward even larger wafer sizes, which will become the new global standard in the next few years.

Read more … Sonnenstromfabrik installs machinery for new generation of PV modules

Sonnenstromfabrik setzt auf vollautomatisierte Endfertigung für PV-Module

Die SONNENSTROMFABRIK (CS Wismar GmbH), einer der modernsten und qualitativ führenden Hersteller von Photovoltaik-Modulen in Europa, hat die Vollautomatisierung der Endfertigung seiner hochwertigen PV-Module erfolgreich abgeschlossen.

Read more … Sonnenstromfabrik setzt auf vollautomatisierte Endfertigung für PV-Module

Sonnenstromfabrik automatise entièrement sa ligne de finition pour ses modules photovoltaïques

SONNENSTROMFABRIK (CS Wismar GmbH), l’un des fabricants leaders en Europe à proposer des modules solaires de haute qualité à la pointe de la technologie, a terminé l’automatisation complète de la ligne de finition de ses modules photovoltaïques haut de gamme. Dans le même temps, les domaines de l’assurance qualité et du contrôle qualité ont été renforcés. La ligne de production entièrement automatisée produira des modules photovoltaïques dont la puissance totale pourrait atteindre 200 MWc par an. La ligne de finition existante, partiellement automatisée, de SON-NENSTROMFABRIK restera en service afin de garantir une flexibilité de production suffisante pour les produits OEM et modules spéciaux.

Sonnenstromfabrik invests in fully automated final assembly facility for PV modules

SONNENSTROMFABRIK (CS Wismar GmbH), one of Europe’s cutting-edge leaders in manufacturing high-quality photovoltaic modules, has successfully made the final assembly stage of its high-quality PV modules fully automated and strengthened its quality assurance and quality control at the same time. The fully automated production line is equipped to manufacture PV modules with a total annual capacity of up to 200 MWp. SONNENSTROMFABRIK’s existing, partially automated, final assembly facility will remain in operation to ensure sufficient flexibility in manufacturing OEM products and special modules.

Read more … Sonnenstromfabrik invests in fully automated final assembly facility for PV modules